DA Smith drilled at Dominion Energy's Roanoke Rapids FERC-regulated concrete buttress dam located in Roanoke Rapids, North Carolina, in 2007, 2009, 2015, 2020, 2022, and 2024 as part of the dam’s ongoing evaluation of structural integrity. Tasks include core drilling in concrete and bedrock, in situ stress measurements using the United States Bureau of Mines (USBM) Borehole Deformation Gage (BDG) method, optical and acoustic borehole imaging, core logging, permeability testing, and the installation of various geotechnical instruments, including piezometers, multiple point borehole extensometers (MPBX), inclinometers, vibrating wire soft inclusion stress cells, thermistors, solar-powered telemetry systems, and dataloggers, as well as commissioning of a real-time online monitoring portal.

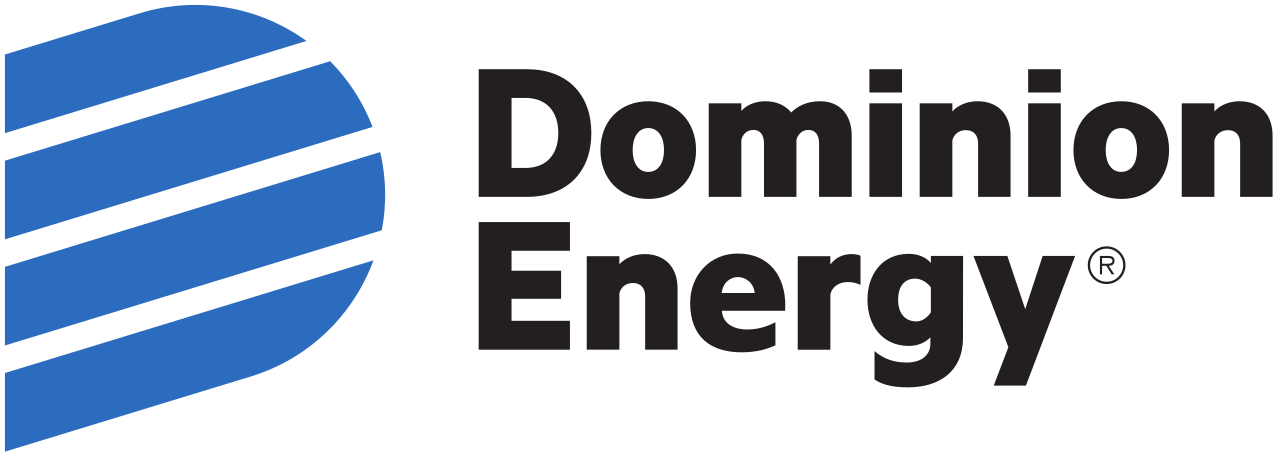

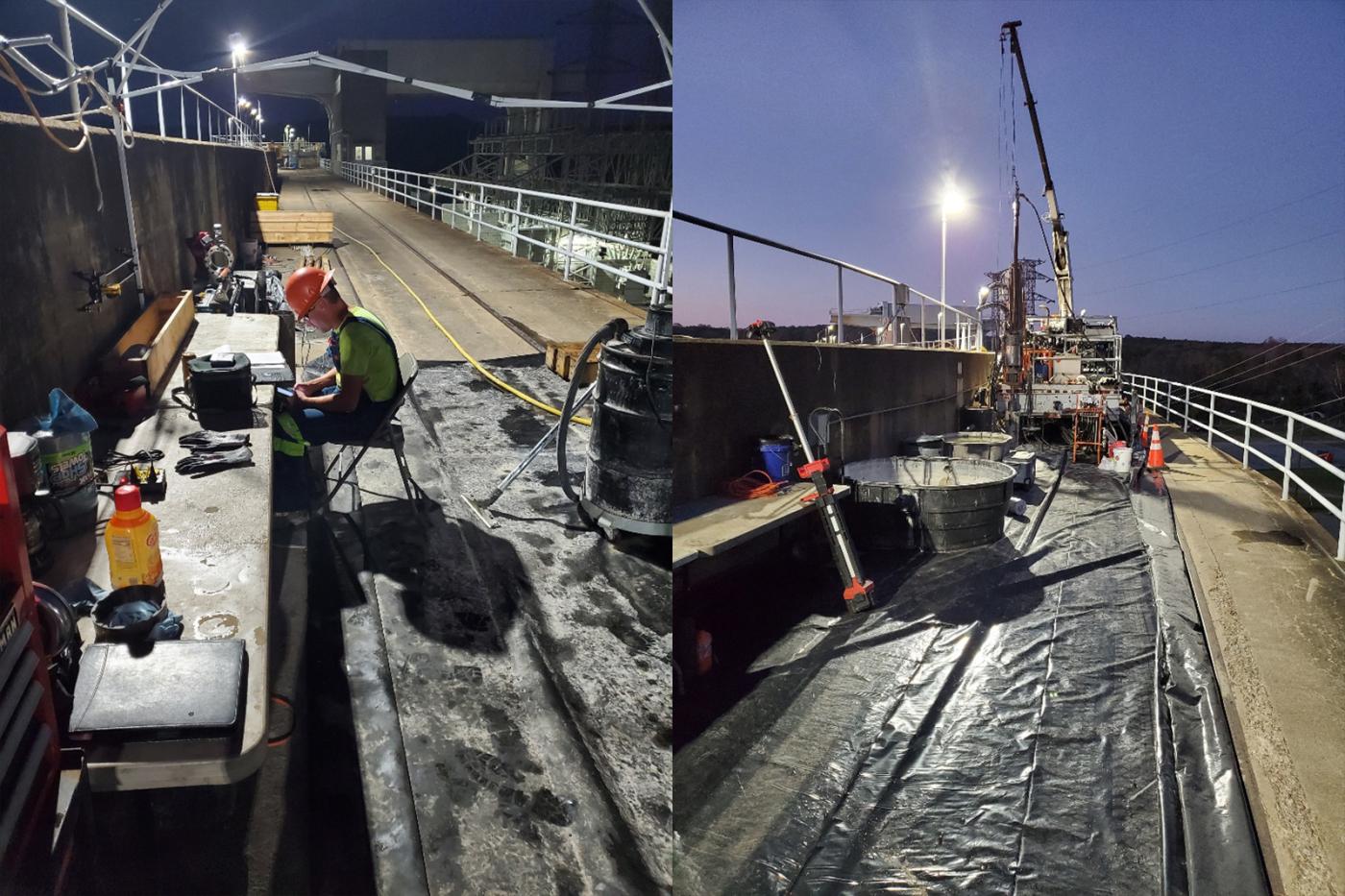

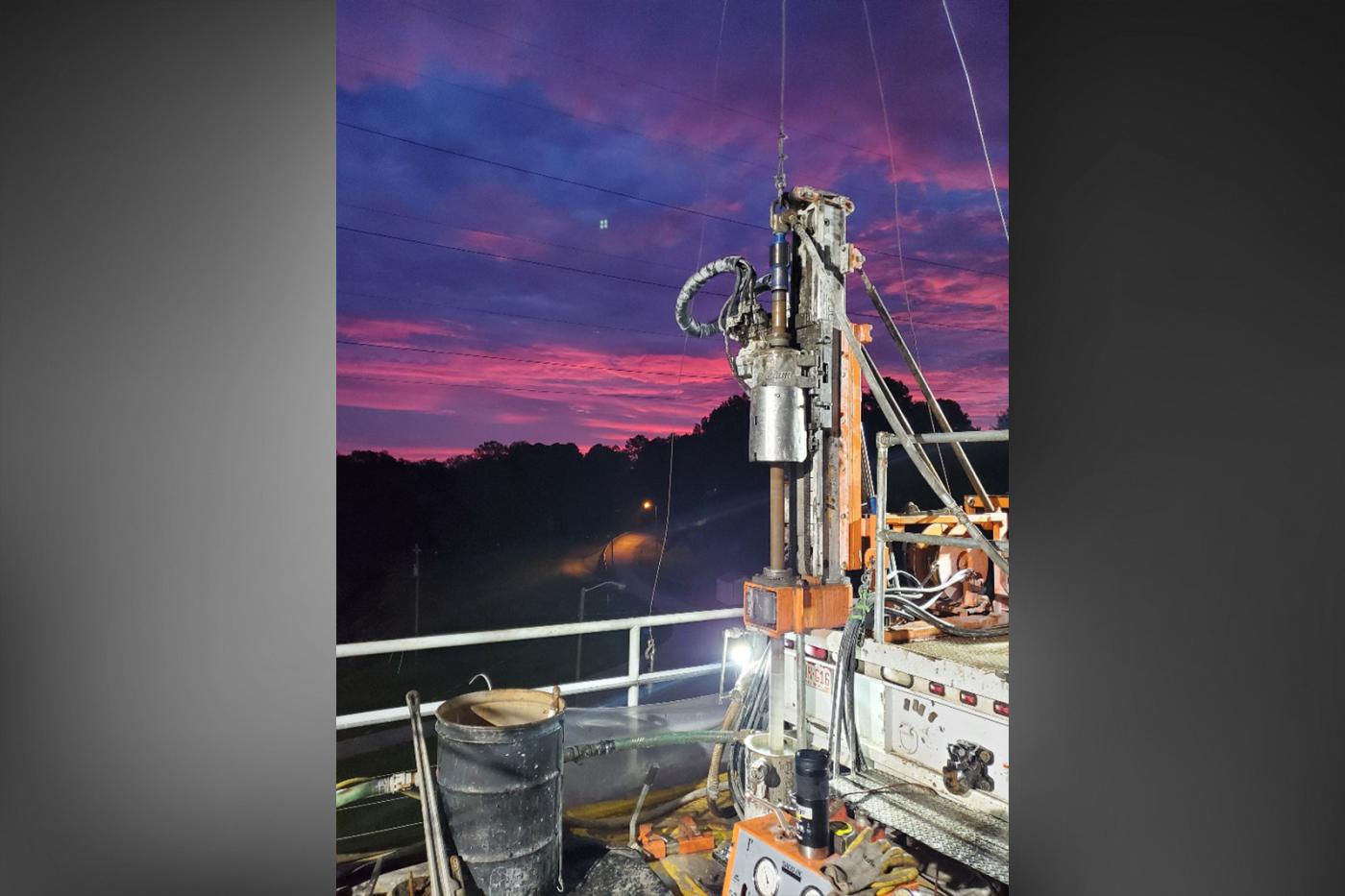

Projects involved surface and in-gallery drilling, sometimes requiring special access equipment including mobile cranes, the dam’s gantry crane, boats, barges, and scaffolding. Strict standards for fluid containment and recirculation were successfully implemented. DA Smith's drillers were vetted and approved by FERC for drilling on the dam based on their training and experience.

2024

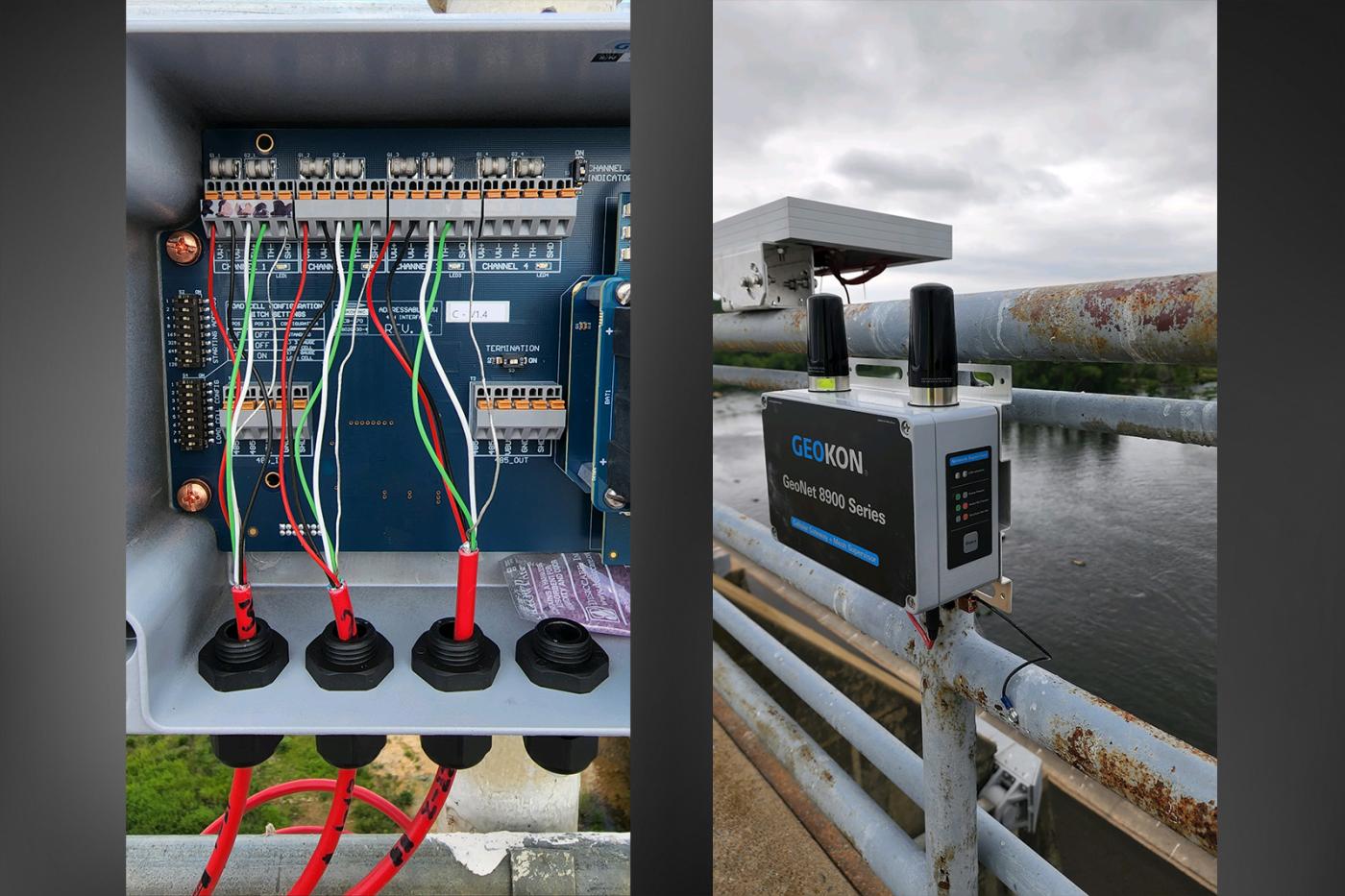

DA Smith subcontracted to Geosyntec Consultants to drill multiple PQ and 6.8-inch-dia. core holes for instrumentation on the dam non-overflow section and inside the dam inspection gallery. DA Smith installed one subvertical multiple point borehole extensometer (MPBX) through the full concrete profile of the dam. Precision holes were drilled from surface into the dam gallery to host vertical pendulum displacement monitoring instruments. Additional holes were drilled inside the dam into the floor of the gallery to bedrock to host inverted pendulums. Pendulum anchors were grouted by tremie line. Instrumented holes were completed with conduit ports and flush-mounted, water-tight caps on surface.

2020-2022

In 2021-22, DA Smith completed 67 in situ stress measurements in concrete and bedrock at the Roanoke Rapids Dam using the USBM BDG method. The project also included the optical televiewer logging of the holes, installation of Geokon® Soft Inclusion Stress Cells (SISCs) to monitor long-term stress changes inside the dam, inclinometers, and a telemetry system for remote stressmeter monitoring.

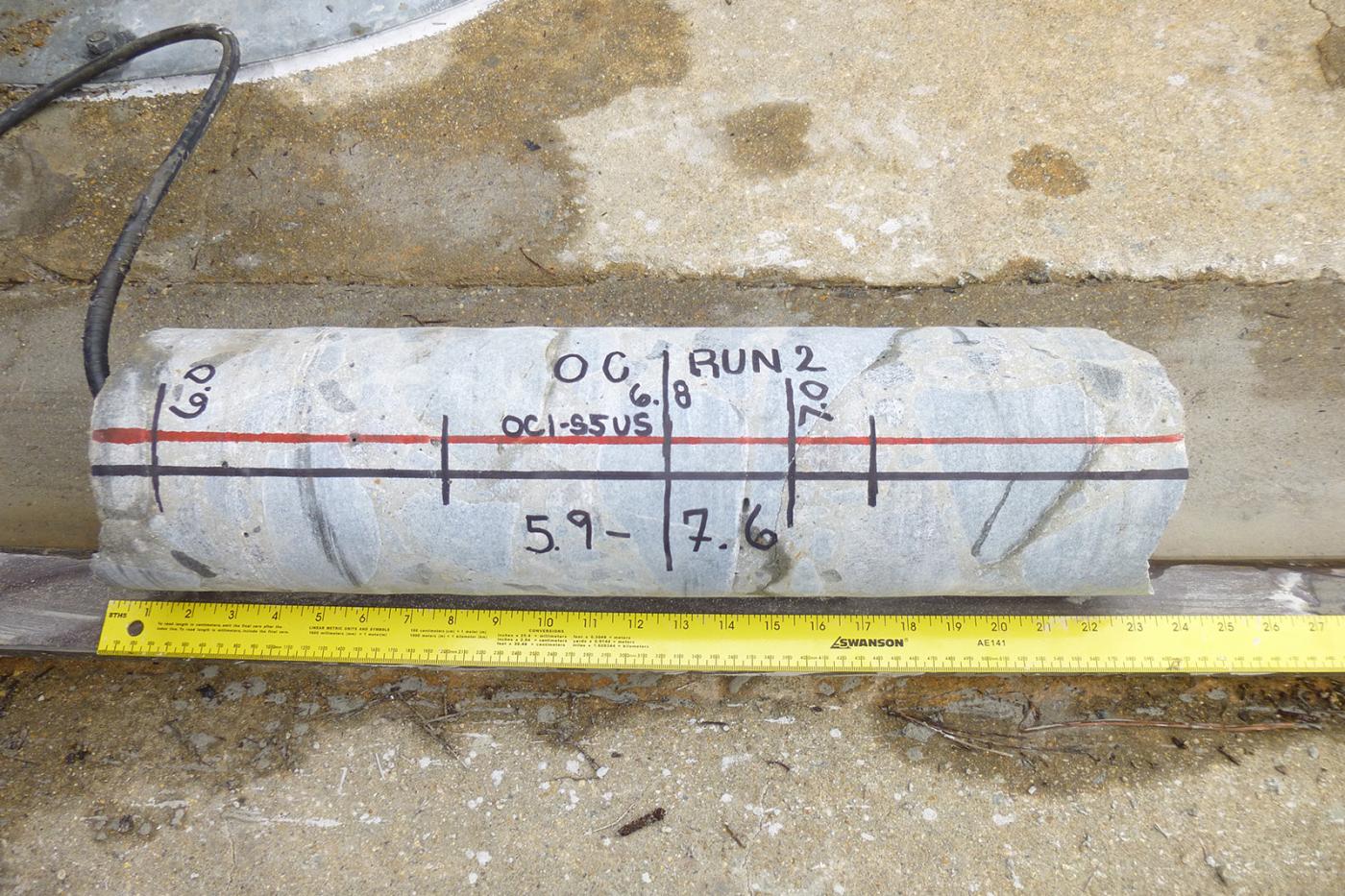

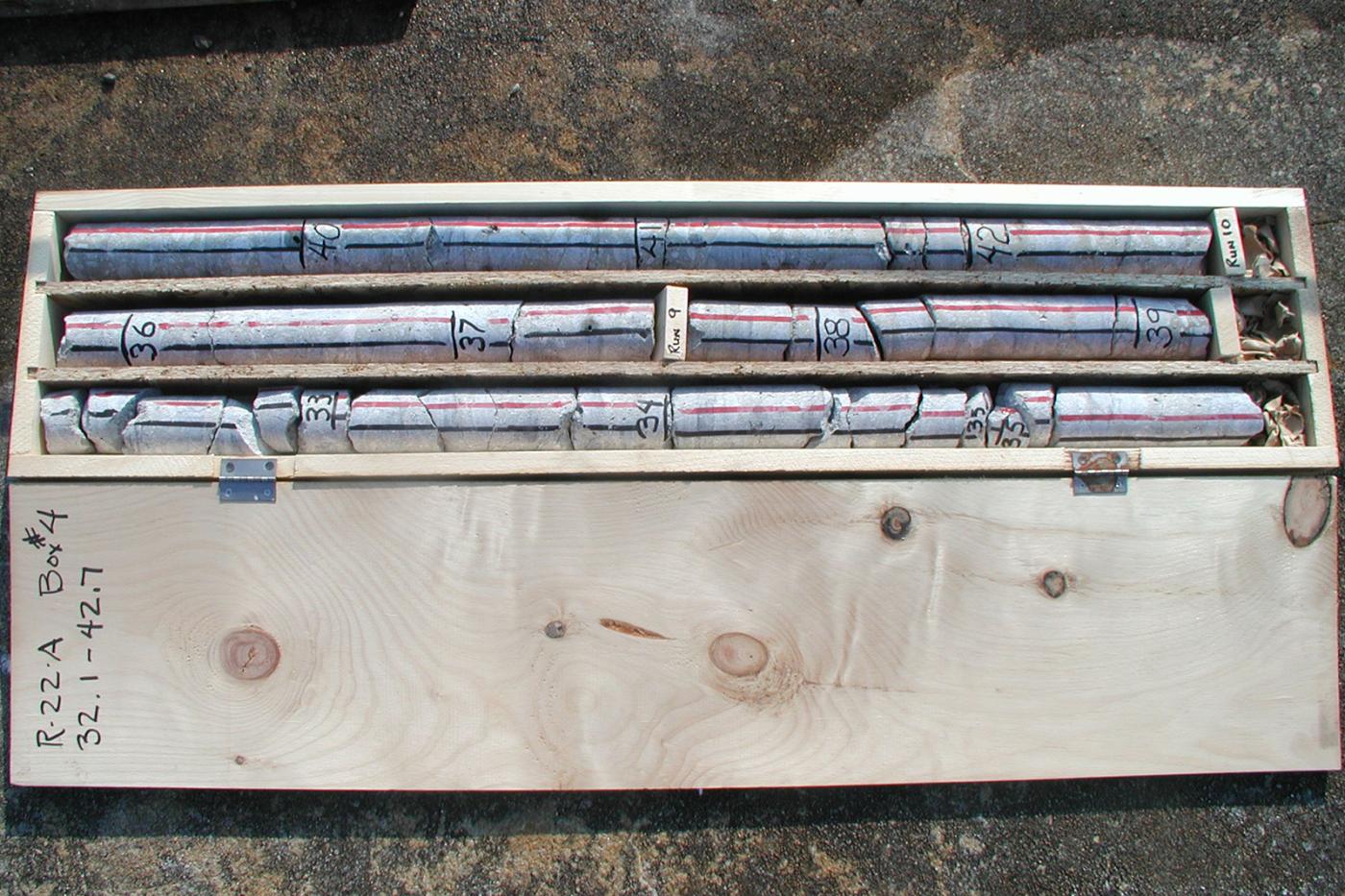

In 2020, DA Smith drilled three vertical exploration core holes on the South Non-overflow Section of the dam to measure in situ horizontal stresses in the core of the dam and foundation bedrock. The 2020 holes twinned similar holes drilled by DA Smith in 2014. A total of 51 USBM BDG overcore stress measurements were completed, providing comparative data with stress measurements taken in 2014. Optical and acoustic televiewer logs were produced for each borehole. Fracture tables with stereo net diagrams were generated from discontinuities digitally mapped in the borehole walls. Holes were completed with DGSI (Slope Indicator) 2 ¾-inch-diameter quick connect inclinometer casing. Ultimately, campaign results were documented in a comprehensive technical report.

2007-2015

In 2007, on behalf of Gannett Fleming, DA Smith* completed the following drilling, instrumentation, and in situ stress measurement campaign:

- Drilled two 6-inch-diameter core holes vertically through the dam and into the foundation.

- Drilled four HQ3 core holes through the dam for observation and instrumentation.

- Completed two stress determination holes using the USBM BDG overcore method. A total of 18 stress measurements were made at depths ranging from 6.5 to 63.5 feet deep.

- Installed vibrating wire piezometers, lightning-protected proving rings, and dataloggers.

- Performed high-resolution borehole imaging of all holes.

- Core drilled through the emergency spillway from the narrow crest of the dam.

- Two of the drill sites were on the emergency overflow section of the dam that is less than 6 feet wide. The drill rig was disassembled down to five parts at the toe of the dam, and then lifted to the crest of the dam with a high-reach crane and reassembled. A work deck was built on-site to provide a safe work location on the narrow crest.

Core was structurally logged, depth marked, striped, photographed, and boxed. A high-resolution borehole image was made of each borehole. Holes were grouted with cementitious grout.

Vibrating wire piezometers and proving rings were installed with lightning protection and connected to a data logger system. Signal cables were run through conduit. A summary report of all field activities, stress determinations, core logs, borehole images, and instrumentation installation details was generated.

In 2009, a similar drilling and instrumentation campaign was completed in support of ongoing engineering investigation:

- Installed two inclinometer casings in HQ core holes drilled through the dam and 50 feet into bedrock.

- Installed three SISCs in Block 26 of the emergency spillway.

- Video surveyed holes using a WC1750 Slimline Dual View Camera.

- Conducted permeability testing of the foundation bedrock.

- Complete unconfined compressive strength (UCS) tests on selected samples of concrete and bedrock.

- Prepared a final report.

In 2014-15, DA Smith* completed core drilling and 74 USBM BDG overcoring runs in seven vertical holes up to 62 feet deep to measure in situ stress. Measurements were conducted according to specifications prepared by HDR Engineering, Inc. of the Carolinas, and were ultimately used for thermomechanical modeling of the dam.

* Formerly as Agapito Associates, Inc.