DA Smith is skilled in casing advancer drilling for applications in boulder-laden alluvium, colluvium, and rubblized ground. Boulders and cobbles are common in unconsolidated overburden throughout much of the Western U.S. Auger drilling in these environments can be unproductive and vulnerable to binding on rocks, flight damage, and false early bedrock refusal. False refusal due to boulders or cobbles risks incomplete geotechnical profiling which can lead to costly mischaracterization of design parameters.

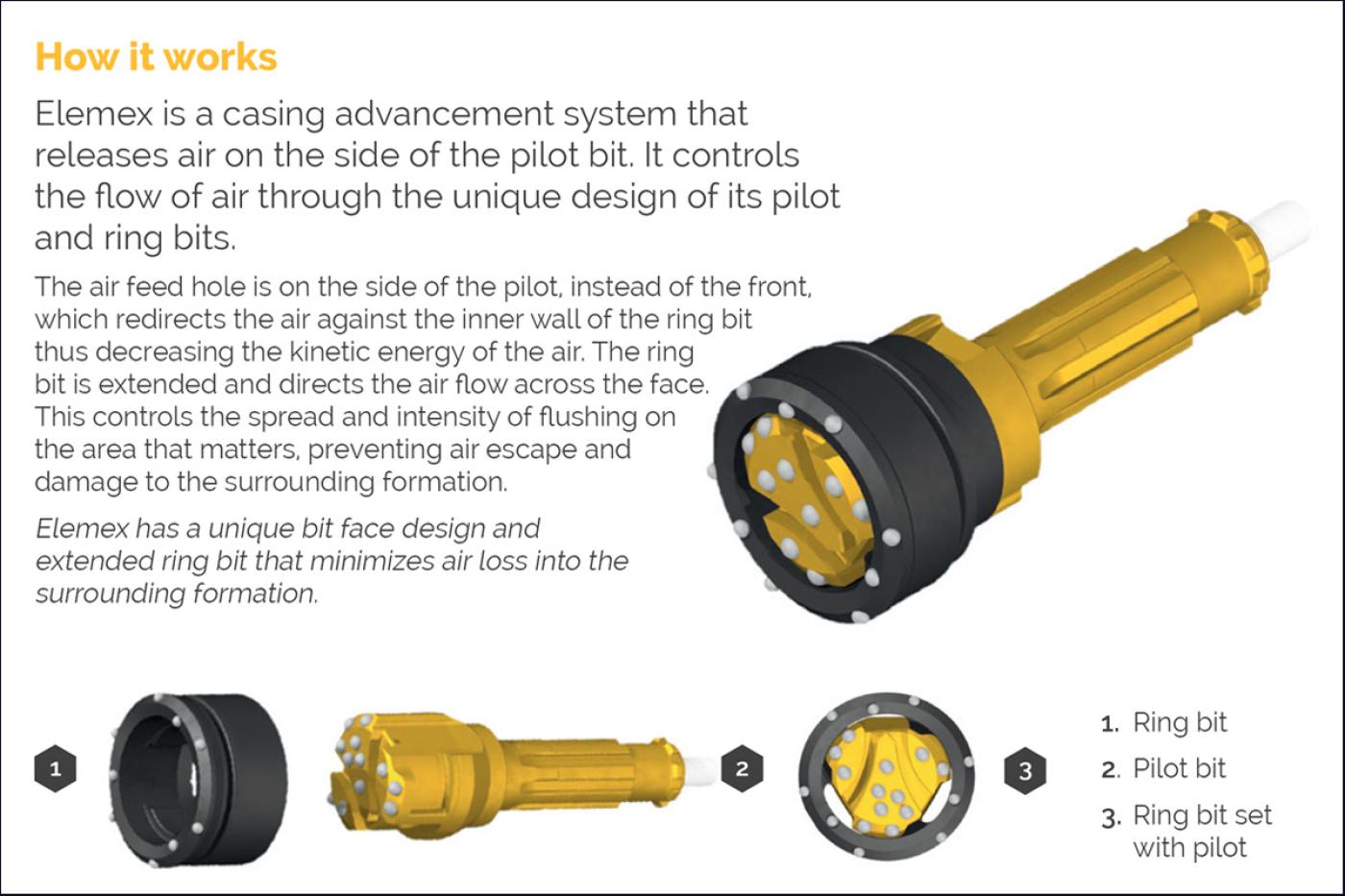

DA Smith operates the state-of-the-art Symmetrix-Elemex air-powered casing advancer system manufactured by TerraRoc. Symmetrix-Elemex is a improved version of ODEX, also made by TerraRoc, that rotates with a symmetrical (round) casing shoe instead of ODEX's eccentric underreamer, the advantage being the elimination of problems associated with underreamer binding and trajectory deflection that can occur with ODEX in cobbled ground.

DA Smith also operates rotary-only casing advancers (no air hammer) using water as the drilling fluid for applications requiring casing for ground control but are not suited to high-pressure air, such as drilling and sampling in earthen embankment dams where fracking is a concern.

Casing advancer drilling with air is capable of rapid penetration through any type of overburden. Efficient geotechnical sampling is conducted through the casing by tripping out the downhole hammer inner string and re-entering with the desired sampler, comparable to the cutter head retrieval and sampler deployment cycle conducted with hollow stem augering (HSA).

Bedrock (refusal) can be confirmed by drilling past any apparent bedrock contact. This can be done with the casing advancer or by core drilling below the casing where core is desired.

Confirmatory bedrock drilling is especially important where thin, hard lenses impervious to augering may overlie and otherwise mask design-critical expansive, unconsolidated, or flowing material.

With the casing advancer method, the temporary casing and ring bit are retrieved when a hole is completed, or can be left in place where permanent steel casing is desired. DA Smith commonly drills with a 5.5-inch O.D. casing advancer and DTH air hammer, which allows holes to be completed through the casing, via the casing pull-back method, as water monitoring wells with up to 4-inch-diameter standpipes. The method is well suited to the efficient installation and grouting of inclinometer casing in weak overburden.

Casing advancer drilling is capable of penetrating and drilling past large voids, such as through rip rap, dissolution cavities, mine entries, or tunnels and galleries in dams.

The casing advancer method is versatile and robust, and, in DA Smith’s experience, the preferred geotechnical drilling and sampling alternative to auger drilling in cobbles and boulders.