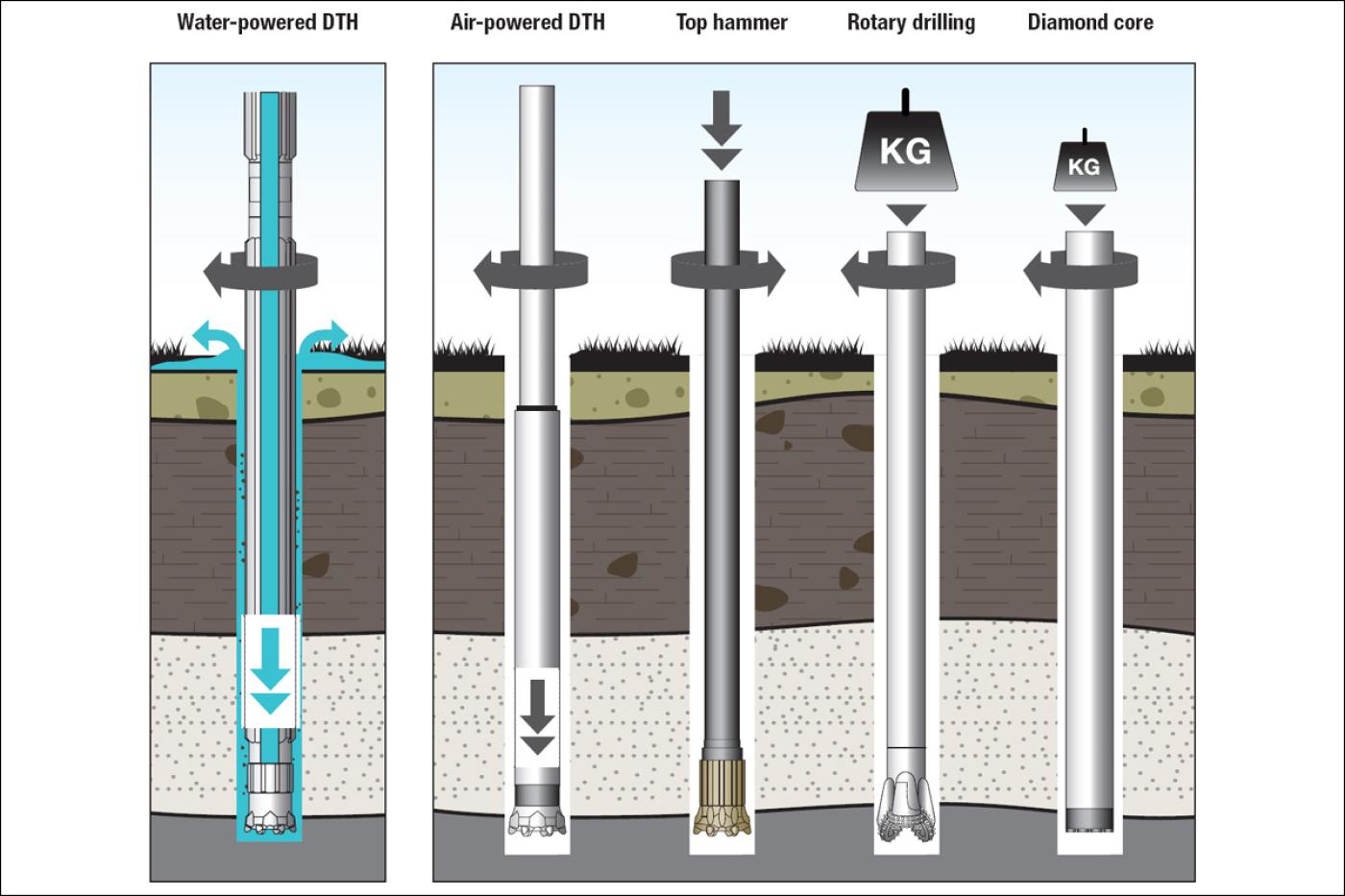

DA Smith performs down-the-hole (DTH) water hammer drilling in rock and concrete where high-productivity drilling and high-tolerance holes are required, and at sensitive sites where air hammer drilling is not allowed. High pressure water is used to power the DTH hammer. Because water is an incompressible medium and air is not, water exits the hammer at low velocity and at hydrostatic pressure while air exits at high velocity and high pressure. Air's high exit pressure risks damaging the rock mass or surrounding structures in sensitive areas such as urban environments and dams. This risk is greatly reduced with water.

Water hammer drilling is especially applicable to drilling in dams where ordinary air hammer drilling is prohibited due to the potential for fracturing the dam or bedrock. DA Smith's experience has proven water hammers to be the best alternative where coring is not required and rotary methods are considered too slow. Key drilling applications include drain holes, anchor holes, grout holes, waterstops, utility holes, and water monitoring wells. Water hammer drilling can be combined with core drilling where pre-collaring or spot core is desired.

DA Smith has been approved on a case-by-case basis to drill with water hammers at FERC-regulated hydroelectric dams.

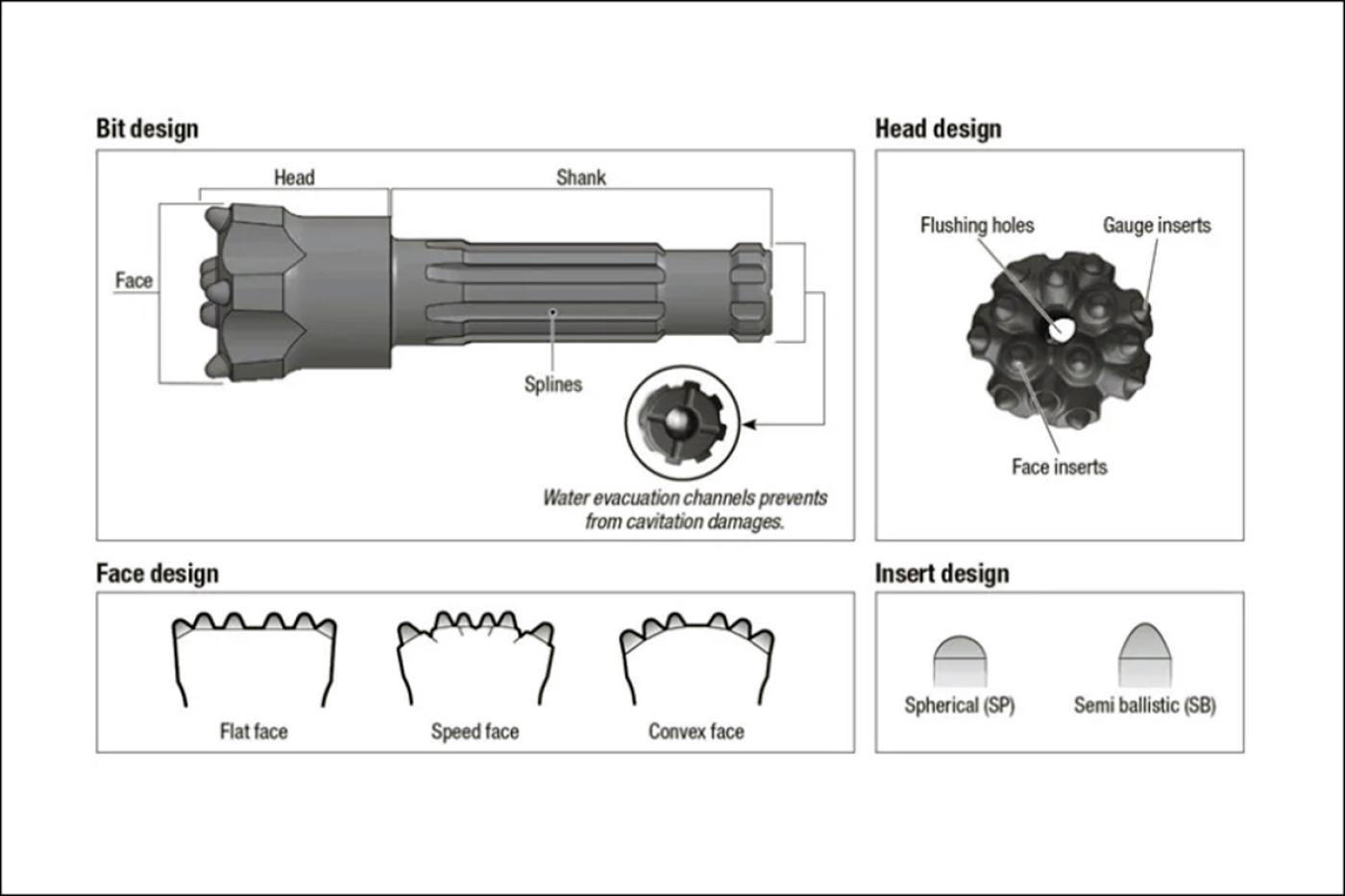

Water hammers use high-pressure water to power the DTH hammer. Water enables a high frequency and high power output. When the water leaves the hammer it has a sufficient velocity to bring the cuttings to the surface and clean the hole. In addition to clean and straight holes with a minimum of deviation, water hammers offer benefits including high productivity, borehole quality, minimum impact on the formation, quieter operation compared to air, and no dust.

Another significant difference occurs when drilling below the water table with inflowing groundwater from the surrounding formation. A 650-ft borehole full of water is equal to a 650-ft water column. When drilling with an air-powered DTH system, this water column must be lifted, generating a 290 psi pressure loss. A water-powered DTH system will not suffer from this since there is water both on the inside and outside of the drill string. The only pressure losses that need compensating are friction and shock losses inside the drill string and the differences in density (water versus slurry).

- Hole diameter 3, 4, and 5 inch

- Distance up to 1,000 feet

- Any angle (vertical up through horizontal to down)

- On surface

- Underground

- Inside dam galleries

- Pre-collaring exploration holes

- Fluid recirculation (zero discharge) possible where free drainage is not allowed

- Hole deviation surveys

- Optical and acoustic downhole surveys (with subcontracted geophysical firms)