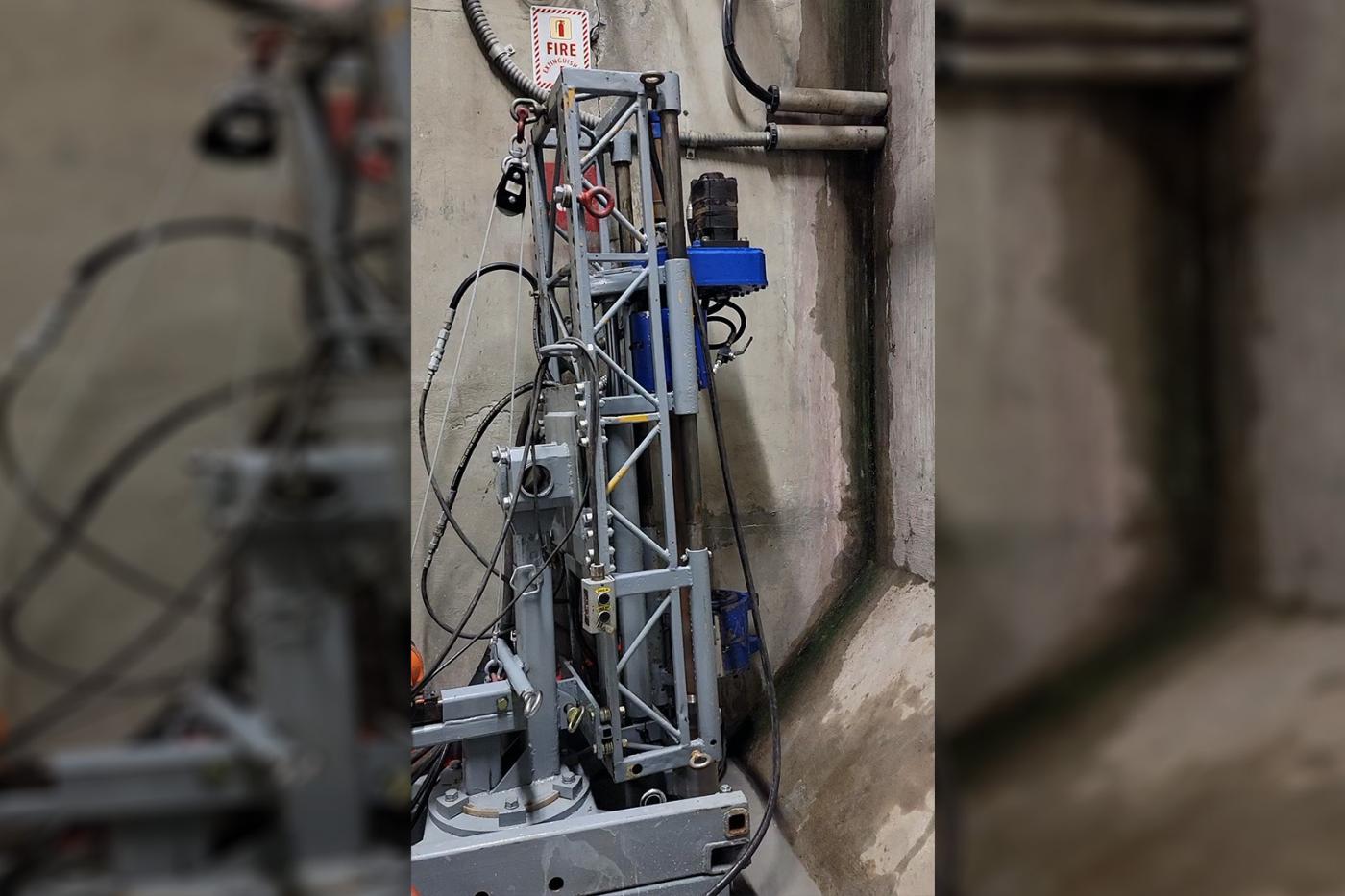

In 2021, DA Smith completed core drilling inside the Grand River Dam Authority's US Federal Energy Regulatory Commission-regulated Robert S. Kerr hydroelectric dam located near Pryor, Oklahoma, on behalf of Oklahoma State University. The dam is located on the Neosho River at Lake Hudson. PQ3 core holes were drilled inside the lowest level of the dam’s powerhouse through concrete and into the bedrock foundation of the dam. Drilling required the use of tight-access, electric-hydraulic equipment that could be maneuvered and set up inside the narrow working spaces of the powerhouse. Borehole pressure testing was completed at select horizons in the bedrock using inflatable straddle packers. Holes were grouted upon completion.

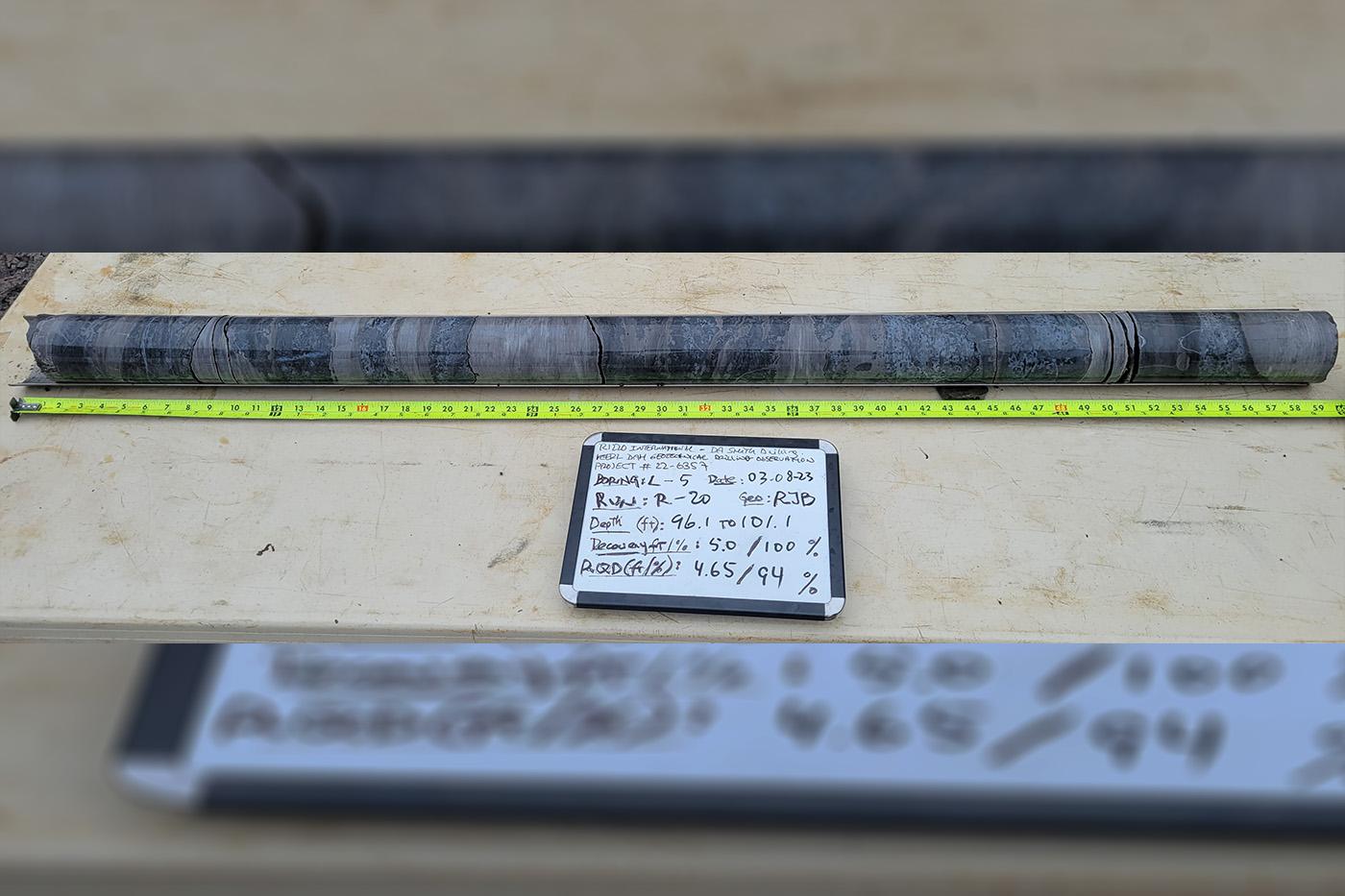

DA Smith returned in 2023 to complete five specialized borings from surface into the bedrock below and surrounding the dam. Holes were drilled with a combination of hollow-stem auger and casing advancer tooling through native and manmade material, then PQ3 cored into bedrock to final depths reaching 215 feet. Both vertical and angled holes were drilled. Soil testing/sampling and Lugeon (constant head permeability) water tests were conducted at regular intervals in all holes.

Specialized drilling methods were required due to the presence of pressurized natural gas in the subsurface, not typical of ordinary geotechnical programs. Drilling was conducted through a specialized diverter and blowout preventer (BOP) system developed for the project. The diverter system allowed gas to be sealed in the hole at the hole collar and released under control remote from drilling operations. Gas was monitored and documented using on-person and remote-area samplers with network communication.

Two holes were completed with piezometers and another completed with a combined piezometer and packer-isolated gas venting system.

Geologic oversight and logging was provided by Rizzo International, Inc., subcontracted by DA Smith. Downhole logging was performed by Colog, Inc.

The surface program was completed safely and efficiently, delivering key data for assessing foundation conditions beneath the dam.